1. Introduction –

In heavy-duty industrial applications like mining, construction, and material handling, one of the most critical challenges is equipment longevity. Constant exposure to abrasion, impact, and harsh conditions causes rapid wear and tear of machinery parts. This not only leads to frequent downtime and maintenance but also escalates operational costs. Industries have long been in search of a durable, high-performance material that can withstand such punishing environments.

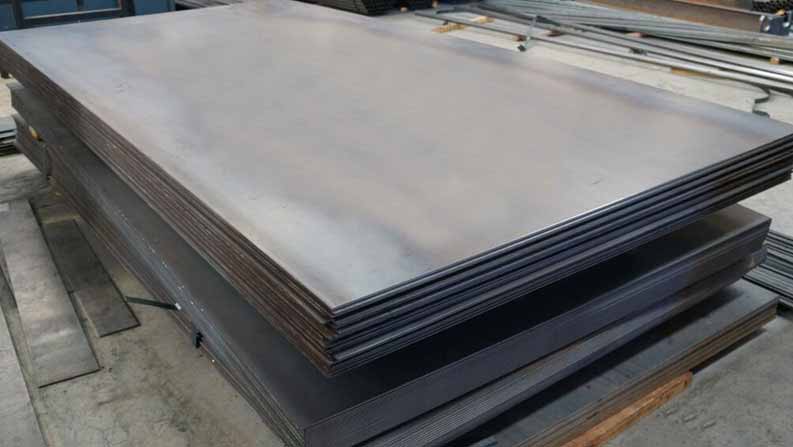

2. Product Introduction –

Enter Rockstar 450 Plate – a high-strength, abrasion-resistant steel plate specifically designed to tackle wear-intensive environments. Manufactured using advanced metallurgy and heat treatment processes, Rockstar 450 offers a perfect balance between hardness and toughness. With a nominal hardness of 450 HBW (Brinell Hardness), it is engineered for durability and performance, making it an ideal choice for demanding applications.

3. Advantages of Rockstar 450 Plate

Exceptional Wear Resistance: Designed to endure constant abrasion, it significantly extends the service life of components.

High Strength-to-Weight Ratio: Delivers structural strength without adding unnecessary weight.

Excellent Impact Toughness: Maintains structural integrity even under high-impact and low-temperature conditions.

Formability and Weldability: Despite its hardness, Rockstar 450 is easy to fabricate and weld, reducing processing costs.

Consistent Quality: Uniform mechanical properties ensure predictable performance across batches.

Cost Efficiency: Longer lifespan means fewer replacements, less downtime, and lower maintenance costs.

4. Real-Life Uses of Rockstar 450 Plate

Rockstar 450 Plate finds widespread use across several industries:

Mining: Lining of dump truck bodies, loaders, crushers, and hoppers.

Construction: Bulldozer blades, excavator buckets, and wear strips.

Material Handling: Conveyor systems, transfer chutes, and silos.

Recycling Plants: Shredder parts, liners, and wear panels.

Agriculture: Harvester parts and tillage equipment.

5. Problem Solving & Outcomes

By integrating Rockstar 450 Plates into their machinery and structures, companies directly address the problem of premature wear and component failure. The outcome is:

Reduced Equipment Downtime: Fewer replacements lead to longer operational cycles.

Lower Operational Costs: Improved durability cuts down maintenance and repair costs.

Enhanced Productivity: Reliable performance means operations can run smoother and faster.

Improved Safety: Stronger materials reduce the likelihood of sudden failures, enhancing workplace safety.

6. Conclusion

In industries where durability is non-negotiable, Rockstar 450 Plate emerges as a game-changer. With its superior wear resistance, strength, and toughness, it not only extends equipment life but also enhances overall operational efficiency. Whether you're in mining, construction, or recycling, Rockstar 450 is the plate you can rely on for long-lasting performance.